Login

Login

Register

Non Galvanized pressed grates steel sheet-type

лв.352,31 – лв.870,07 without VAT.

Pressed grills made of non-galvanized steel sheet, made by welding, are ideal for the quick and easy construction of various constructions, such as overpasses, gap closures, platforms, stands and many other such projects. Non-galvanized steel gratings are not zinc coated and have a dull, gray appearance, are durable and easy to install.

Select options

This product has multiple variants. The options may be chosen on the product page

Pressed steel grating P load-bearing bar in width

лв.75,09 – лв.219,11 without VAT.

Pressed steel grating P load-bearing bar across the width or short direction of the grill, specially built to last and provide long-term strength and durability. It can be used in any field, both for residential areas and for industrial needs. The design of the grill is efficient and strong enough to prove its competence in terms of safety and durability in the industrial field.

Select options

This product has multiple variants. The options may be chosen on the product page

Pressed steel grating P longitudinal bearing bar

лв.75,09 – лв.219,11 without VAT.

A Pressed Steel Grating P Longitudinal Bearing Bar is a high-strength, high-load-bearing product, easy to install, with a wide range of applications. Pressed steel grating P consists of longitudinally pressed load-bearing bars, offering high load-bearing capacity and outstanding characteristics for a range of industrial and domestic applications.

Select options

This product has multiple variants. The options may be chosen on the product page

Pressed Steel Grating P With Serrated Flat Bar 30/10 mm

лв.142,86 – лв.178,57 without VAT.

Pressed steel grating P with serrated flat bar 30/10 mm, thermally galvanized, weighing 20.5 kg, designed for a wide range of applications. The design of the grating provides constructions with a well-individualized and, at the same time, resistant profile, easily adapting alongside other construction materials.

Select options

This product has multiple variants. The options may be chosen on the product page

Pressed Steel Grating P-profile with Fluted Plate and Mesh 30/10 mm

лв.124,13 – лв.199,61 without VAT.

Pressed steel grill P edged with 30/10 mm mesh flat band, hot-dip galvanized and weighing 20.5 kg, designed for a wide range of applications. The design of the grill gives the constructions a well-individualized and at the same time resistant profile, easily adapting to other construction materials.

Select options

This product has multiple variants. The options may be chosen on the product page

Standard grating 30×10 mesh U profile

лв.36,29 – лв.164,67 without VAT.

Standard grating 30×10 mesh U profile, hot-dip galvanized by total immersion, obtained by bar-to-bar pressing, with each load-bearing point intersection. They are some of the most common gratings in the industry and are frequently used in construction and industrial applications as a floor surface for mezzanines, walkways, walkways, steps, foot traffic and other platforms.

Select options

This product has multiple variants. The options may be chosen on the product page

Standard U-profile grates 30×30

лв.36,31 – лв.164,92 without VAT.

Standard grill mesh 30×30 U profile, thermally galvanized by total immersion, pedestrian, with different sizes. These grills are a smart choice for a wide range of projects. Not only are they incredibly durable and weatherproof, but they also have many convenient features that make projects easier to complete. In addition, the elegant design will fit perfectly into any space.

Select options

This product has multiple variants. The options may be chosen on the product page

Welded Steel Grating SP eye 34/38 mm

лв.71,43 – лв.537,64 without VAT.

Sp mesh welded steel grill 34/38 mm, made of S 235 JR steel, fully dip galvanized, designed for projects that need a durable product, able to withstand harsh weather conditions and heavy use. The load-bearing structure of the grill is created from steel strips, the stability of which is ensured by spacer bars. Its attractive design will add personality to the outdoor space.

Select options

This product has multiple variants. The options may be chosen on the product page

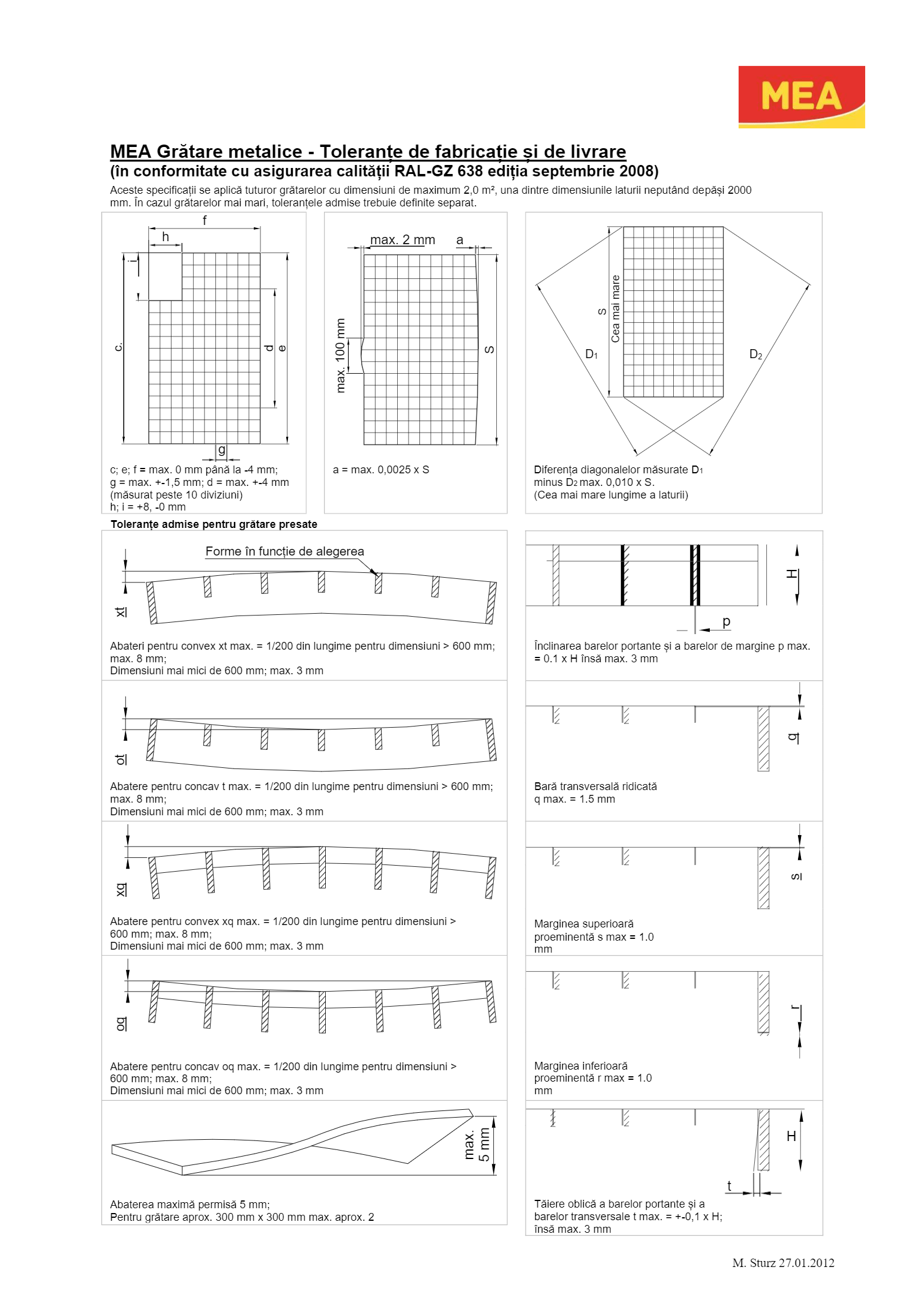

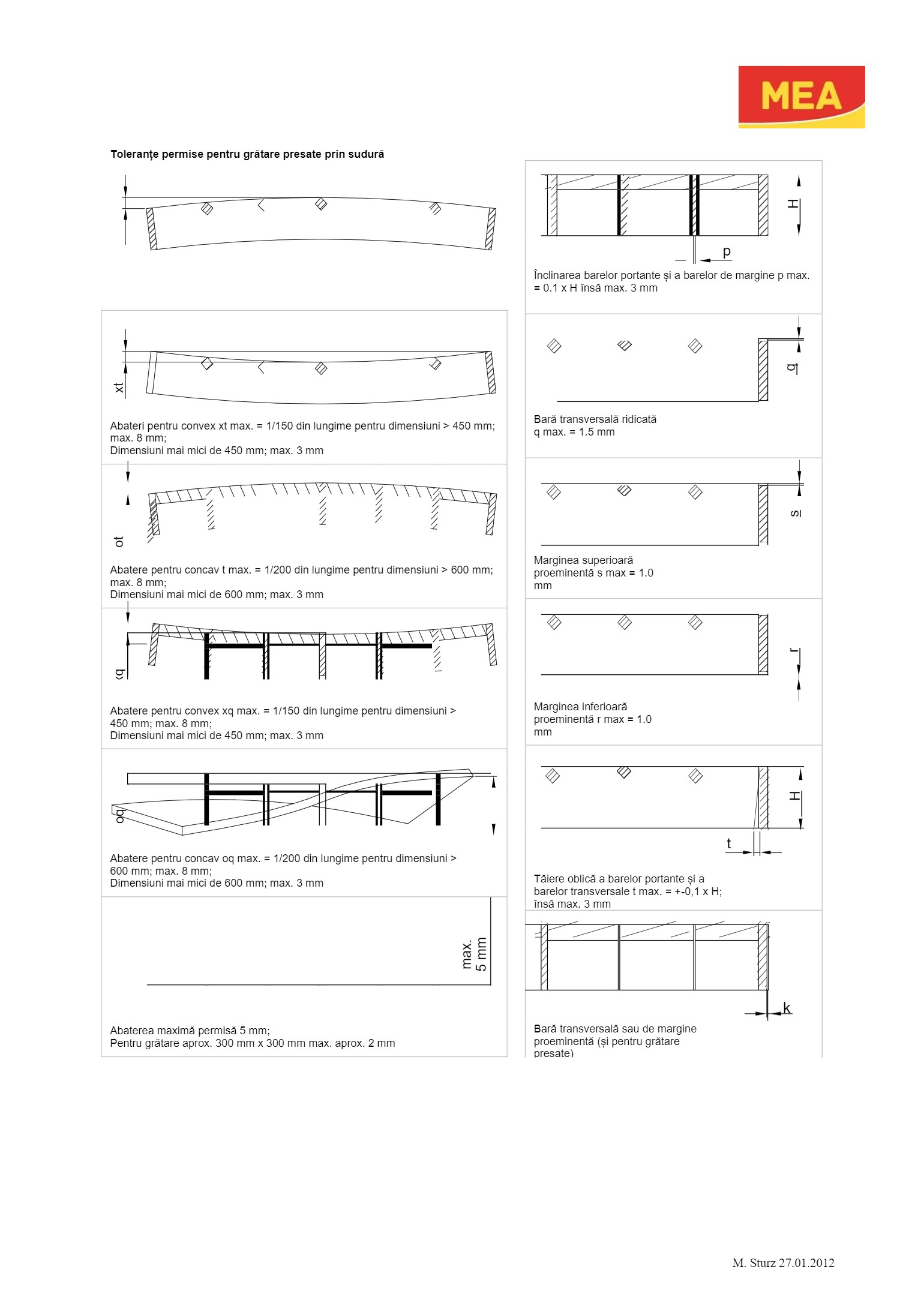

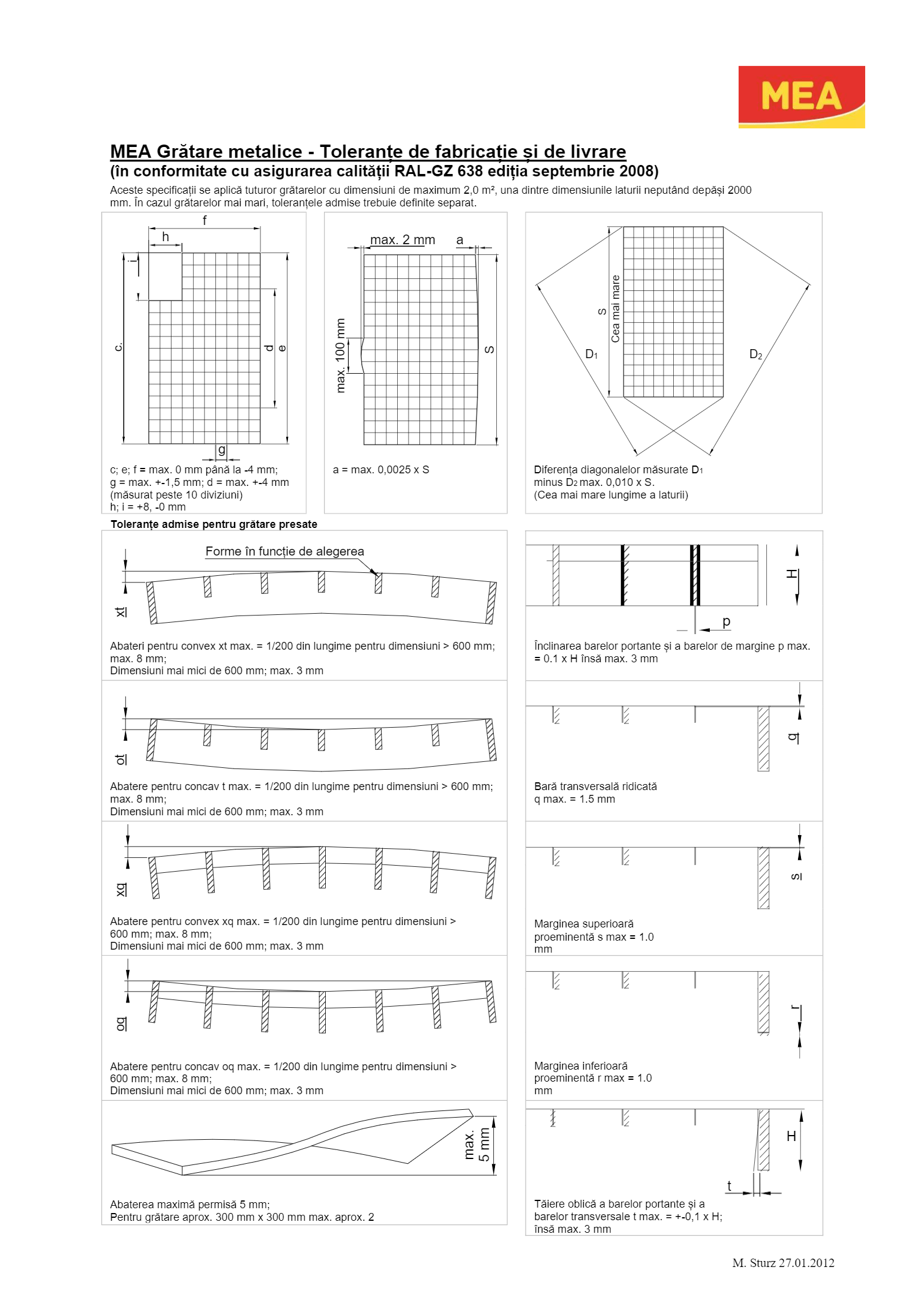

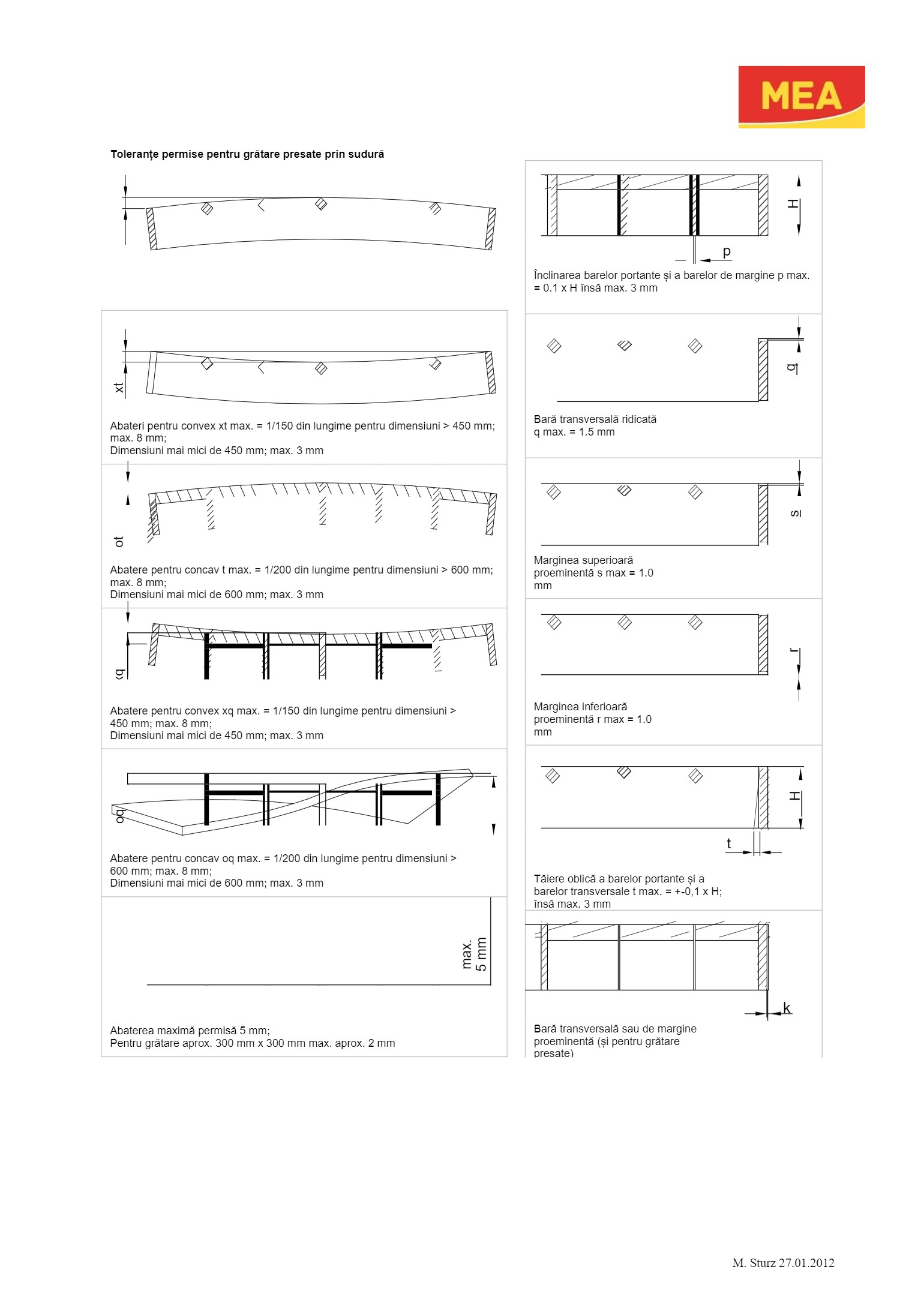

"Metal gratings are functional elements, industrially manufactured, for which the following must be observed:

- Dimensional tolerances of the gratings correspond to the attached data sheet (according to RAL-GZ 638). These tolerances can be guaranteed up to an area of 2 m² and/or a maximum length of the side of 2,000 mm. Additionally, these tolerances are no longer valid in accordance with RAL-GZ 638.

- The supporting bars of the gratings (top bars) must be supported at both ends on a substructure with at least 25 mm. This is the only way to dissipate the forces that occur.

- Metal gratings can be offered in hot-dip galvanized steel or stainless steel.

The following must be observed, especially in the case of hot-dip galvanized steel (according to DIN EN ISO 1461): (The evaluation is made from a distance of 1 m with the naked eye)

o Small defects, where the zinc absorption is not sufficiently present, are treated again with suitable agents (e.g., zinc spray). This subsequent remediation is usually visible. This does not constitute a defect of the product.

o Zinc flakes or small zinc peaks and inclusions on the zinc surface may be present between the mesh. Also, small surface irregularities of the zinc may appear. All these do not constitute a defect of the product.

o Due to external influences, white rust may form on the grating surface. This can be easily removed, for example, with a copper brush. This does not constitute a defect of the product.

o Hot-dip galvanized items are initially shiny silver and become matte gray after a few weeks. This is a physical process and does not constitute a defect of the product."

- We recommend not walking barefoot on a grating. Among other reasons, because, in general, steel components can heat up significantly when exposed to sunlight and, therefore, pose a risk of injury. Additionally, welding splatters and zinc peaks may be present.

- We recommend not walking barefoot on a grating. Among other reasons, because, in general, steel components can heat up significantly when exposed to sunlight and, therefore, pose a risk of injury. Additionally, welding splatters and zinc peaks may be present.

- We recommend not walking barefoot on a grating. Among other reasons, because, in general, steel components can heat up significantly when exposed to sunlight and, therefore, pose a risk of injury. Additionally, welding splatters and zinc peaks may be present.

- We recommend not walking barefoot on a grating. Among other reasons, because, in general, steel components can heat up significantly when exposed to sunlight and, therefore, pose a risk of injury. Additionally, welding splatters and zinc peaks may be present.Filter Products by Price

Product Categories

- Accessories (5)

- Frames for Metal Gratings (2)

- Metal Gratings (8)

- Metal Stair Kits (3)

- Metal Stair Treads (3)

- Rolling Hardware (76)

- Floor Guides (5)

- Guide rails (4)

- Handles & Limiters (30)

- Sliding door kits (1)